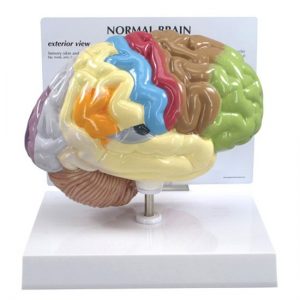

“Our Values: At GPI we strongly believe in the potential of anatomical models to positively impact the lives of patients, students and healthcare providers around the world. We also believe that our employees are the individuals best suited to help us accomplish our mission.”

— Adam Galloway

Management Team

Scott Galloway

CEO

Scott founded GPI Anatomicals in 1980 and maintains an active general management role. His background in plastics manufacturing dates back to his father’s furniture manufacturing company during the 60’s and 70’s. Since then, he has gone on to develop a wide range of products from olympic memorabilia to cereal box toys. For over 30 years, he has focused his talents on the medical field in developing this full-service provider of anatomical models and pharmaceutical sales aids.

Adam has been with GPI for over 10 years and currently manages all sales and marketing efforts within the organization. He also oversees project management as it relates to new product development and customized solutions for our most valued clients. Adam is focused on maintaining GPI’s reputation as the world’s most reliable and innovative provider of patient education materials.

Jon has been an integral part of GPI Anatomicals for over 10 years and has been in the industry for over 30. He currently oversees all manufacturing and design processes. He and his staff are dedicated to consistently developing high quality products at reasonable prices. This process includes everything from idea-creation and customer approvals to quality control and shipping logistics.

Want to join our team? E-mail us

Frequently Asked Questions

-

Are you hiring?

At GPI we are constantly on the lookout for standout talent and we are currently accepting applications for highly-motivated sales and marketing professionals. If interested please send a copy of your resume to careers@gpianatomicals.com

As a family owned business, we have a long tradition of treating each employee as a member of our extended family. We go to great lengths to encourage teamwork and foster strong relationships.

The success of GPI Anatomicals is due in large part to the people behind the scenes. Our leadership team is dedicated to talent development and increasing our profitability wherever possible.

-

What are your capabilities?

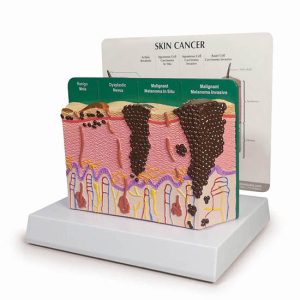

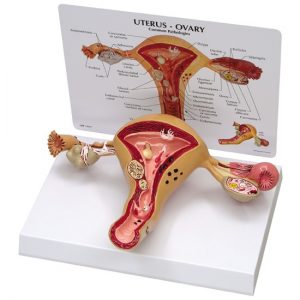

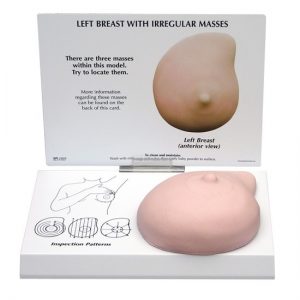

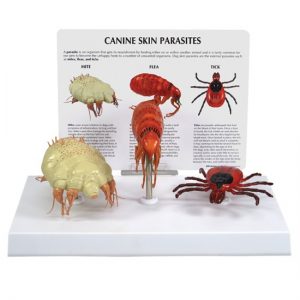

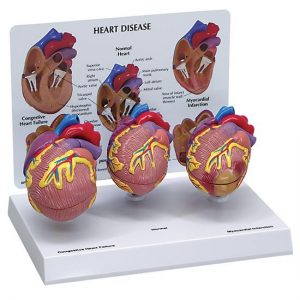

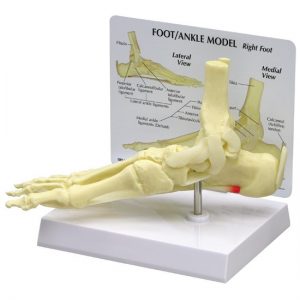

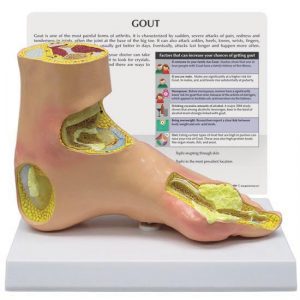

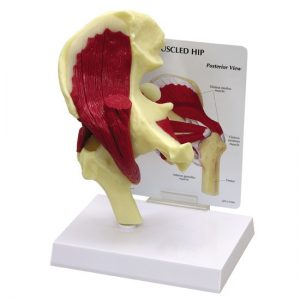

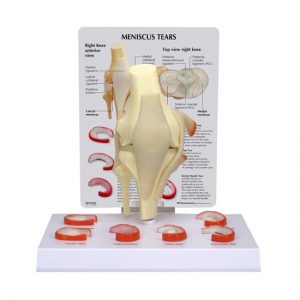

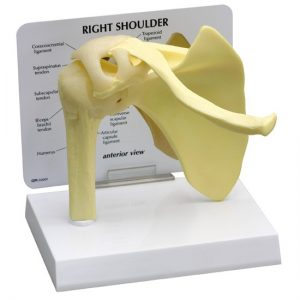

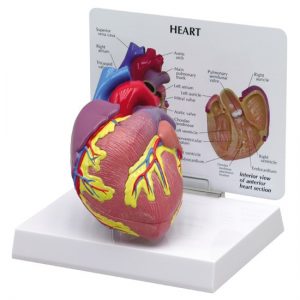

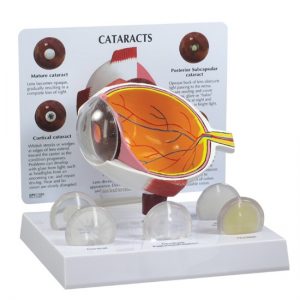

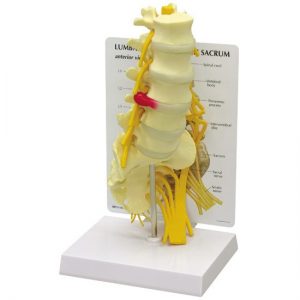

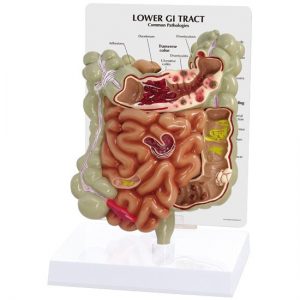

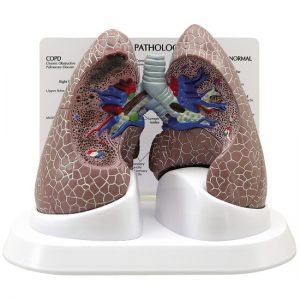

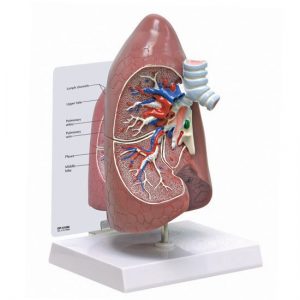

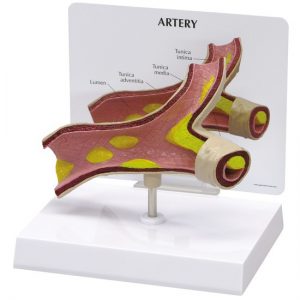

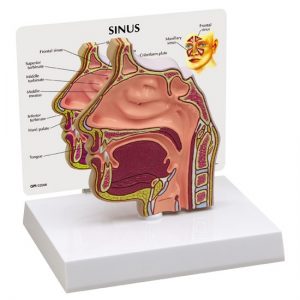

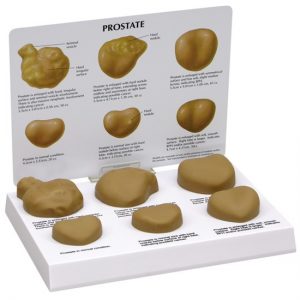

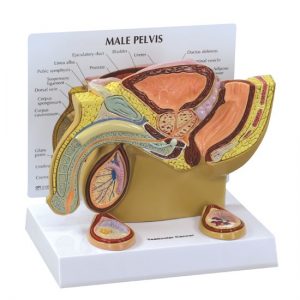

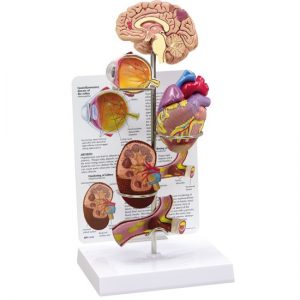

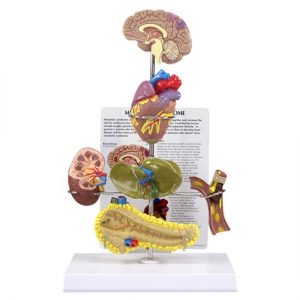

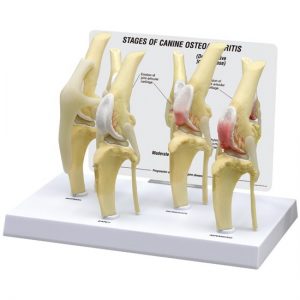

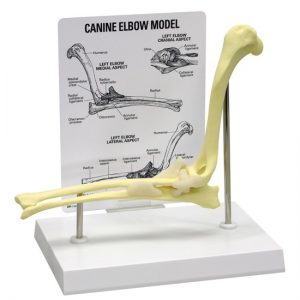

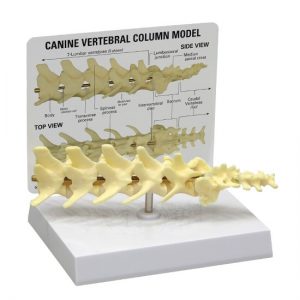

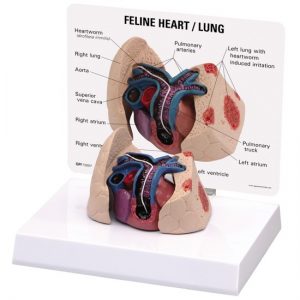

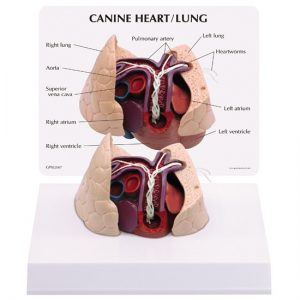

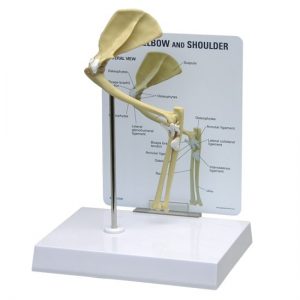

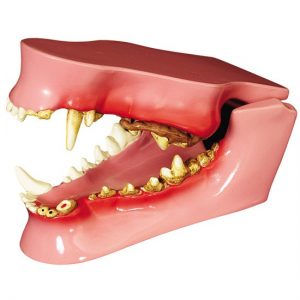

GPI Anatomicals has worked with a wide range of clients and has replicated/presented hundreds of medical devices and implants. A small list of our capabilities include medical device replicas, reproductions of bone plates and joint replacements, implant replicas, and custom bone replicas.

We’ve been managing custom pharma and patient educational model projects for over 30 years and have worked with every major pharmaceutical company around the world. We make every effort to improve the quality of our products, reduce any inefficiencies and add innovative capabilities in an effort to continually expand our level of expertise.

We are constantly innovating our design and manufacturing processes so if you have an idea, share it with us and we’ll find a way to make it a reality.

Have Another Question?